You normally don’t see rounded fret ends on guitars because they take too much labor. But this is changing.

On most acoustic and electric guitars, frets are installed typically by cutting a slot all the way across the neck, installing fretwire across the neck, then clipping the fretwire ends so that you get self-alignment of the fret with the neck width. Then the fret ends are filed/sanded for smoothness.

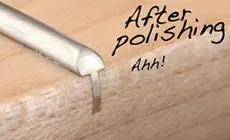

Here is an example:

After clipping the frets, you have to hand file and sand the fret ends smooth. Due to the nature of the fret ends and neck edge, this sanding normally creates a triangular beveled shape at the edges that align with the neck. It is not rounded.

If done in this way, you will normally see the fret tang at the neck edges. This is very typical on necks that are not bound, like on a vintage Strat:

On bound necks, the slots are cut all the way across but stopping short of the binding. The tangs are cut to only fit the slots. Everything else is the same. You still have to trim the fret, then file the edges after they are installed.

If you file the edges after fret install, this is why you get the triangular beveled ends. But is also self-aligning. You have to be careful of the neck but you’re just sanding in just one direction to reduce the square, sharp edges.

This way of installing frets is most typical and can be fast. You slot the frets, install the frets, clip the ends, and file the edges to form the smoothed edge, then polish. The frets are perfectly aligned to the edges.

Why would you want a more rounded fret end? Well, it will make a difference but only for some players. If you play fast and your hand moves up and down the fretboard often, and you use the neck as a guide (which almost all do), then the edge of your hand will almost always contact the fret edges. The conventional fret edge is a little sharp sometimes and will catch your inner hand. It is acceptable, but not as comfortable as a fret that is rounded. The same goes for the fretboard edges, which many luthiers today "roll" by sanding the edges to be rounded. This is the same idea.

However, if you want a more polished fret end – like something rounded, and don’t want the tang to be visible or have a bound neck – then this becomes a lot more laborious. It is even more labor if the frets are SS (stainless steel) as these are harder and require more work. It requires a lot of manual filing and sanding for each fret end (for 22 frets, that is 44 ends). You have to be very careful not to nick or scratch the neck, and also have to be consistent on the rounding for each fret as this is done by eye. So this is both labor intensive and requires discipline and skill. This equates to much higher cost.

Another method which saves some time but is still labor-intensive is to pre-cut the fret wire before install.

Here is an example:

This example is a refret with SS fretwire. Note the fret slots don’t go all the way across since it is bound. The frets are pre-cut as you can see and installed.

In this example, you still have to dress the fret ends after install, so this is still more labor!

To get nice frets with no visible tang and rounded ends involves a lot of labor. Using SS is even worse because it is harder to file and sand. This is why you don’t see it on budget guitars. Until – the Asian makers figured out how to do it economically.

One way to do it in high volume and limit human labor is to:

Note that 1-3 can be automated if done correctly. 4 still needs to be done by hand, but this should be easy and fast. There’s no sanding or fret dressing of the ends by a human, which takes the most labor.

Here is an example of a rounded fret install on a <$300 guitar from China, an EART NKC3 in 2021. What is interesting here is that you see the fret tang area filled in. This is not normal. What likely happened here is that the neck already had fret slots cut all the way across, and they likely filled it in. Then they did this new process.

The downside of this new fret install process is that the frets could be slightly misaligned from side to side. There is no self-alignment with the neck edge. You can see it slightly in the photo. It’s definitely acceptable and you don’t notice it unless you look very closely. But those rounded fret ends look and feel incredible! And you can't see the fret tangs.

Here is an example on an EART E-335 with a plastic bound neck, like you would see on a Les Paul or ES-335 type guitar. The frets overhand the binding, and you don’t see any fret tangs or refilling of the binding, so most likely the fret slots were cut more precisely rather than all the way across, and the pre-cut and pre-rounded frets installed.

This kind of fret treatment was only previously available on high-end guitars due to the labor cost. But the Asian manufacturers have figured out how to do it cheaply while using stainless steel frets! So now, it’s offered on many guitars that are <$300 while before it was only scarcely seen on guitars >$3000. In fact, many of the known USA guitar makers as of 2022 – Fender, Gibson, PRS, etc. don’t offer this feature AT ALL – rounded stainless steel frets – on any of their guitars – not even high-end models, custom shops, or Private Stock! However, they might do it if you ask nicely (!) -- and they would definitely charge a lot of money for it. Even some boutique makers like Tyler refuse to use SS frets due to tone. Such BS. They don't want to retool! Even some of the best acoustic makers as well as electric guitar makers are using SS frets and they don't hear a detrimental effect.

This is real engineering innovation – bringing great features that used to be very high-end down to the low-end. And this feature is NOT cosmetic. It is extremely practical – having SS frets for great durability and life while having rounded fret ends for playing comfort. And the neck on guitars in my opinion really defines the playability of the guitar. So the Asian manufacturers have focused correctly on where to apply innovation as well as engineering to offer it to more customers on cheaper guitars.

If you look at the engineering involved, it isn’t that complicated. It is common sense. But it takes someone in the industry to look at it differently and want to make it better at lower cost. The USA makers have no desire to do this – only to continue to charge more for less. They would rather spend more money trying to relic a guitar and charge more for this marketing nonsense rather than to make the neck better and charge less.

On most acoustic and electric guitars, frets are installed typically by cutting a slot all the way across the neck, installing fretwire across the neck, then clipping the fretwire ends so that you get self-alignment of the fret with the neck width. Then the fret ends are filed/sanded for smoothness.

Here is an example:

After clipping the frets, you have to hand file and sand the fret ends smooth. Due to the nature of the fret ends and neck edge, this sanding normally creates a triangular beveled shape at the edges that align with the neck. It is not rounded.

If done in this way, you will normally see the fret tang at the neck edges. This is very typical on necks that are not bound, like on a vintage Strat:

On bound necks, the slots are cut all the way across but stopping short of the binding. The tangs are cut to only fit the slots. Everything else is the same. You still have to trim the fret, then file the edges after they are installed.

If you file the edges after fret install, this is why you get the triangular beveled ends. But is also self-aligning. You have to be careful of the neck but you’re just sanding in just one direction to reduce the square, sharp edges.

This way of installing frets is most typical and can be fast. You slot the frets, install the frets, clip the ends, and file the edges to form the smoothed edge, then polish. The frets are perfectly aligned to the edges.

Why would you want a more rounded fret end? Well, it will make a difference but only for some players. If you play fast and your hand moves up and down the fretboard often, and you use the neck as a guide (which almost all do), then the edge of your hand will almost always contact the fret edges. The conventional fret edge is a little sharp sometimes and will catch your inner hand. It is acceptable, but not as comfortable as a fret that is rounded. The same goes for the fretboard edges, which many luthiers today "roll" by sanding the edges to be rounded. This is the same idea.

However, if you want a more polished fret end – like something rounded, and don’t want the tang to be visible or have a bound neck – then this becomes a lot more laborious. It is even more labor if the frets are SS (stainless steel) as these are harder and require more work. It requires a lot of manual filing and sanding for each fret end (for 22 frets, that is 44 ends). You have to be very careful not to nick or scratch the neck, and also have to be consistent on the rounding for each fret as this is done by eye. So this is both labor intensive and requires discipline and skill. This equates to much higher cost.

Another method which saves some time but is still labor-intensive is to pre-cut the fret wire before install.

Here is an example:

This example is a refret with SS fretwire. Note the fret slots don’t go all the way across since it is bound. The frets are pre-cut as you can see and installed.

In this example, you still have to dress the fret ends after install, so this is still more labor!

To get nice frets with no visible tang and rounded ends involves a lot of labor. Using SS is even worse because it is harder to file and sand. This is why you don’t see it on budget guitars. Until – the Asian makers figured out how to do it economically.

One way to do it in high volume and limit human labor is to:

- Pre-cut the fret-slots but not all the way to the edge. This is on any neck, not just bound. This is easily done via CNC.

- Pre-cut the tangs and fret wire width for each fret location. This can also be automated perhaps with a specific machine

- Round and sand the fret ends before install. This can be done like they do with a jeweler cup burr or something similar – perhaps automated.

- Install the frets. This is still done by hand

Note that 1-3 can be automated if done correctly. 4 still needs to be done by hand, but this should be easy and fast. There’s no sanding or fret dressing of the ends by a human, which takes the most labor.

Here is an example of a rounded fret install on a <$300 guitar from China, an EART NKC3 in 2021. What is interesting here is that you see the fret tang area filled in. This is not normal. What likely happened here is that the neck already had fret slots cut all the way across, and they likely filled it in. Then they did this new process.

The downside of this new fret install process is that the frets could be slightly misaligned from side to side. There is no self-alignment with the neck edge. You can see it slightly in the photo. It’s definitely acceptable and you don’t notice it unless you look very closely. But those rounded fret ends look and feel incredible! And you can't see the fret tangs.

Here is an example on an EART E-335 with a plastic bound neck, like you would see on a Les Paul or ES-335 type guitar. The frets overhand the binding, and you don’t see any fret tangs or refilling of the binding, so most likely the fret slots were cut more precisely rather than all the way across, and the pre-cut and pre-rounded frets installed.

This kind of fret treatment was only previously available on high-end guitars due to the labor cost. But the Asian manufacturers have figured out how to do it cheaply while using stainless steel frets! So now, it’s offered on many guitars that are <$300 while before it was only scarcely seen on guitars >$3000. In fact, many of the known USA guitar makers as of 2022 – Fender, Gibson, PRS, etc. don’t offer this feature AT ALL – rounded stainless steel frets – on any of their guitars – not even high-end models, custom shops, or Private Stock! However, they might do it if you ask nicely (!) -- and they would definitely charge a lot of money for it. Even some boutique makers like Tyler refuse to use SS frets due to tone. Such BS. They don't want to retool! Even some of the best acoustic makers as well as electric guitar makers are using SS frets and they don't hear a detrimental effect.

This is real engineering innovation – bringing great features that used to be very high-end down to the low-end. And this feature is NOT cosmetic. It is extremely practical – having SS frets for great durability and life while having rounded fret ends for playing comfort. And the neck on guitars in my opinion really defines the playability of the guitar. So the Asian manufacturers have focused correctly on where to apply innovation as well as engineering to offer it to more customers on cheaper guitars.

If you look at the engineering involved, it isn’t that complicated. It is common sense. But it takes someone in the industry to look at it differently and want to make it better at lower cost. The USA makers have no desire to do this – only to continue to charge more for less. They would rather spend more money trying to relic a guitar and charge more for this marketing nonsense rather than to make the neck better and charge less.